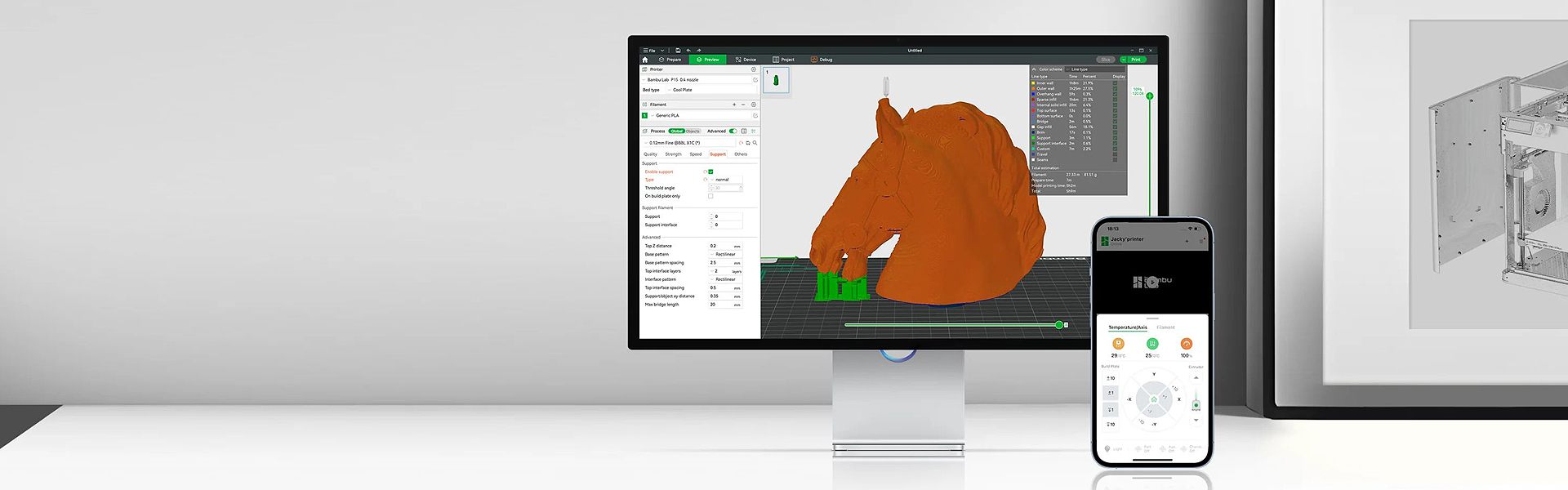

Bambu Lab A1: A Colourful Revolution in 3D Printing

The Bambu Lab A1 is a 3D printer that not only promises innovation but delivers a colourful gateway to 3D printing with its all-new AMS Lite technology. AMS Lite brings elegance and reliability, making multi-colour 3D printing accessible to everyone, ushering in a new era of creativity and convenience.

The Bambu Lab A1 allows for Swift Maintenance: Redefining User-Friendly Design

Quick Swap Nozzles

With an all-new quick-swap hot-end design, the Bambu Lab A1 Combo sets itself apart from other systems in its class. With just one clip, the hot end effortlessly pops in and out, ensuring swift maintenance and reducing downtime. This user-friendly feature enhances the overall experience, making nozzle changes a breeze.

Load/Unload Filament With One Touch

Gone are the days of manual filament adjustments. The A1 automates the filament load/unload process with a one-touch mechanism. No manual settings are required; the A1 streamlines the entire process, making 3D printing more accessible and enjoyable for everyone.

The Bambu Lab A1 features Auto Monitoring and Adjusting: Precision at Every Step

Auto Belt Tensioning

A1 goes beyond the basics by implementing an auto-monitoring system for belt tension. Through vibration frequency calibration, the HMS system checks belt tension automatically. In case of loose tension, the A1 notifies the user to adjust the auto belt tensioner, ensuring optimal printing conditions.

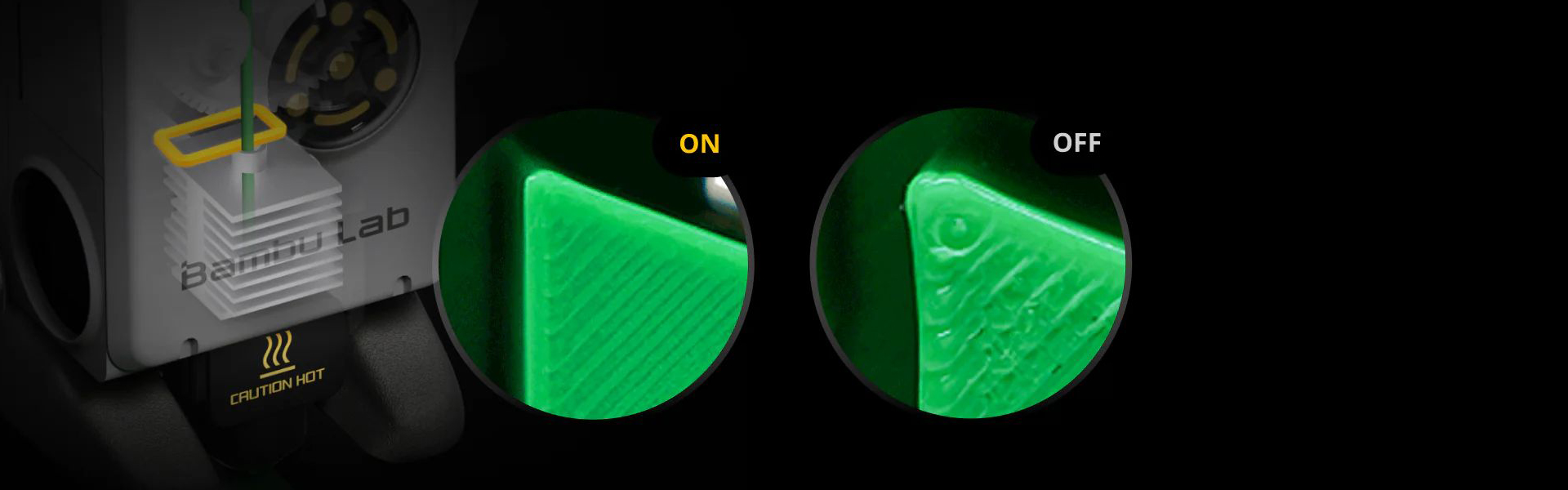

Fully Automated PA (Pressure Advanced) Calibration

In a groundbreaking move, the A1 introduces the Pressure Advanced calibration system. This innovative algorithm handles nozzle pressure-based flow dynamics calibration automatically. No need for manual patterns or pick-and-match procedures; the A1 takes care of Pressure Advanced calibration effortlessly.

Auto-Tune Both X & Y Resonance Before Every Print

A1 pioneer in auto resonance calibration for both X and Y axes. With sensors in the tool head and heat bed, the A1 ensures a precise and harmonious printing experience by automatically tuning resonance before every print. Say goodbye to the manual calibration hassles.

No More “Paper Method”

Bid farewell to the traditional paper method for bed levelling. The A1 revolutionises the process by probing the bed with the nozzle to measure the absolute Z offset. This eliminates the need for manual references, making the printing setup more intuitive and user-friendly.

Goodbye to Tedious Manual Calibration And Tuning

The A1 takes the burden of manual calibrations off your shoulders. Meticulously handling Z-offset, bed-level, vibration resonance, and nozzle pressure for every print job, the A1 ensures that each project is executed with precision and perfection. Say goodbye to tedious manual tuning; let the A1 handle the technicalities while you focus on unleashing your creativity.

In conclusion, the Bambu Lab A1 redefines the 3D printing landscape with its AMS Lite technology and a suite of user-friendly features. Whether you’re a seasoned enthusiast or a beginner, the A1 promises a vibrant and hassle-free 3D printing experience.

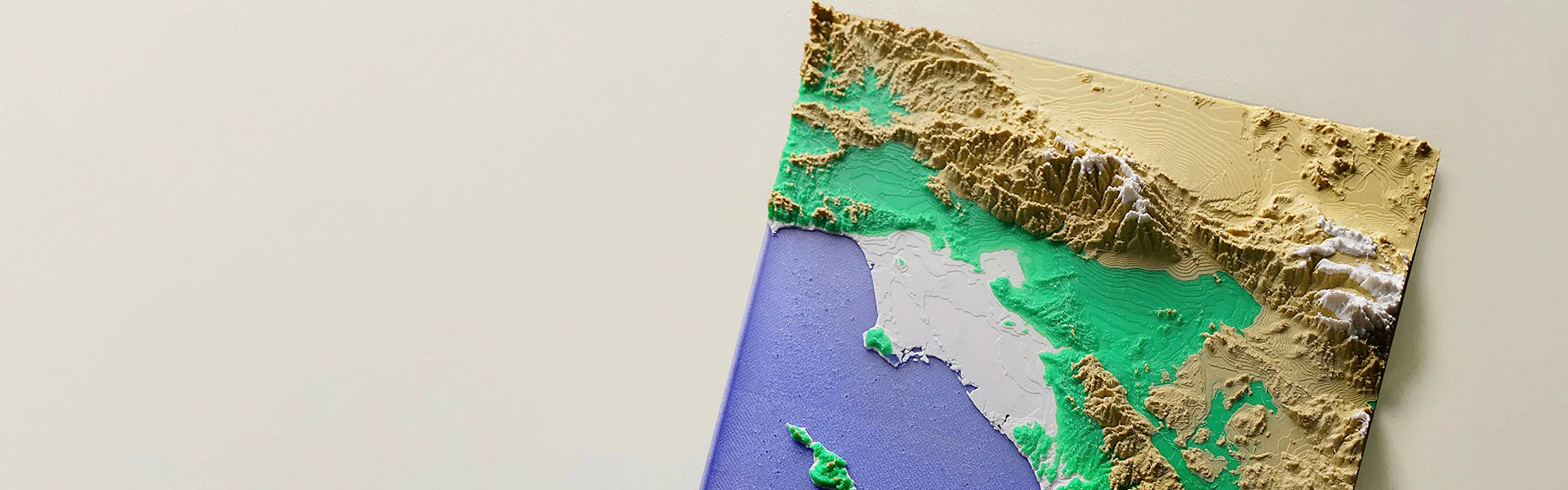

Multi-Colour Printing

The all-new AMS Lite is elegant and reliable, making multi-colour 3D printing accessible to everyone.

Active Flow Rate Compensation

The A1 mini revolutionises flow control in 3D printing. It utilises a high-resolution, high-frequency eddy current sensor to measure the pressure in the nozzle. Our algorithm actively compensates the flow rate according to the readings to extrude with accuracy.

Full Auto Calibration

The A1 mini handles various calibrations all by itself. It meticulously calibrates the Z-offset, bed-level, vibration resonance and nozzle pressure for EVERY print job, automatically.

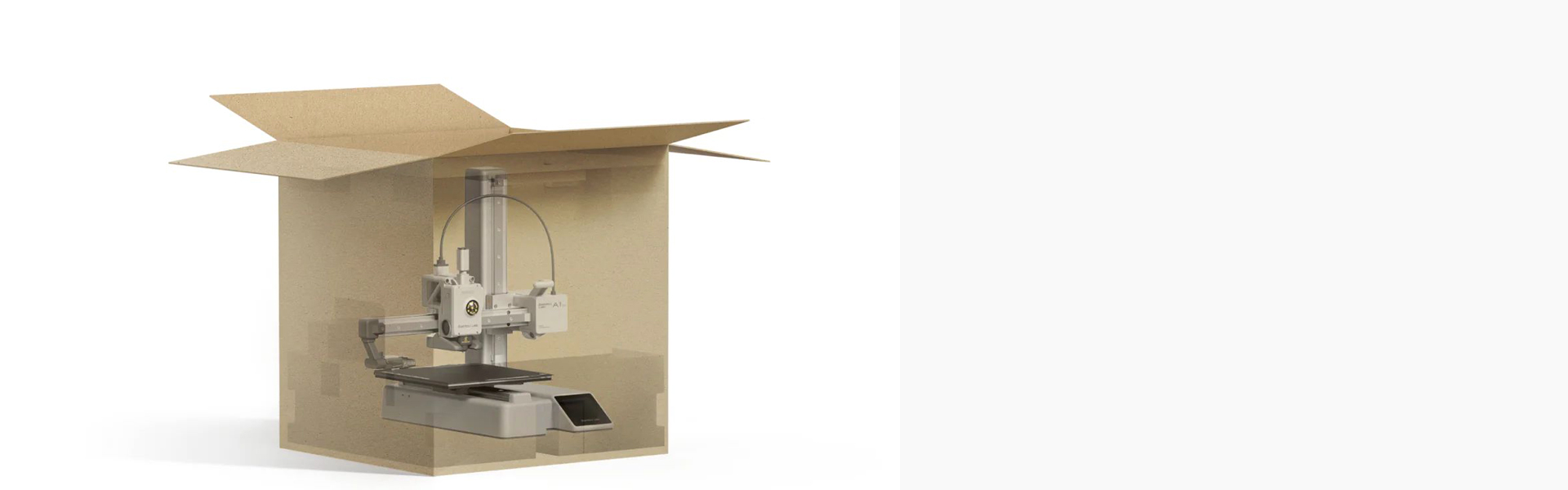

Plug-N-Play

The A1 mini comes to you pre-assembled, pre-squared and pre-tuned with precision. It only takes about 20 minutes to set up for your first print.

Active Motor Noise Cancelling

The A1 mini can calibrate parameters to match tiny individual differences between each drive motor. This compensates for the unwanted harshness of motor noise.

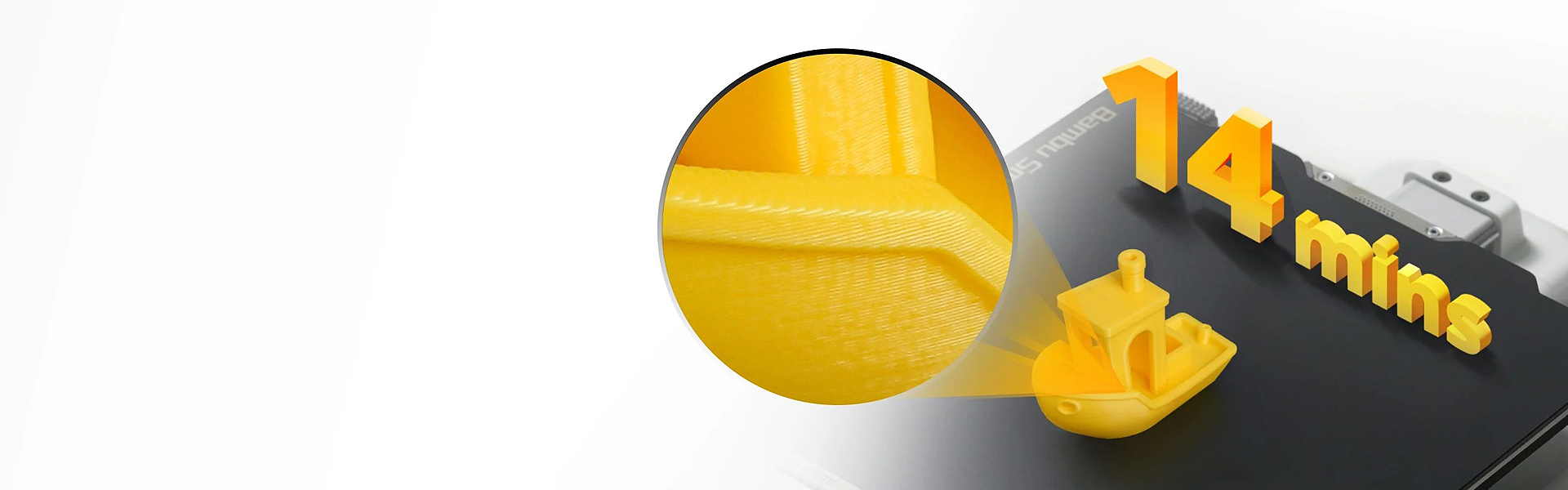

Bed Slinger, with CoreXY Speed And Quality (High-Speed Precision)

Full-metal Rails, rigid frame, nozzle pressure sensor, accelerometers, powerful MCU, and above all, an advanced motion control system that utilises these features to print a 14-minute bench with quality and following all the speed bench rules straight out of the box without using specialised filaments.

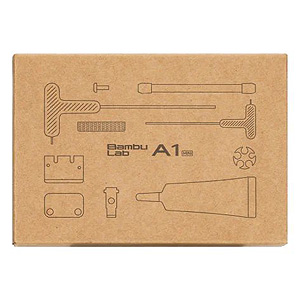

What’s in the box?

- A1 Mini 3D Printer

- AMS Lite

- Spool Holder

- Purge Wiper

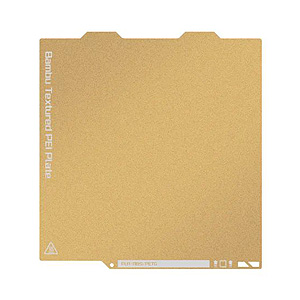

- Build Plate

- PTFE Tube (x 1)

- Bambu Filament Samples (Random Colour)

- Stainless Steel Nozzle (Included)

- Accessory Box

Reviews

There are no reviews yet.