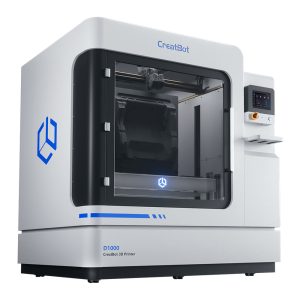

TITOMIC D623 – World’s first medium-pressure cold spray system

The TITOMIC D623 system is used in the repair and restoration of various metal parts, including engine components and moulds. The system is also effective for sealing, corrosion protection, enhancing electrical conductivity, and other specialised applications. Additionally, the TITOMIC D623 system is suitable for applying coatings, such as electrically conductive coatings and corrosion-resistant layers. Whether you’re working with metals, glass, ceramics or plastics, the D623 system unlocks a wide variety of applications.

- Compatible with the ISB-Linear system, including the XY robotic system for repeatable coating and secondary manufacturing operations.

- Deposit dissimilar metals, such as aluminium onto steel, or nickel onto cast iron

- Broad range of metals available. If it is available as a powder, it could be deposited with cold spray.

Features

- Versatile handheld and robotised systems

- Fuse dissimilar metals to create custom solutions

- No excess heat, avoiding cracking and warping

- Create high-performance metal coatings

- Deposit layers of metal with 99% density

- Reduce downtime and replacement costs

- Deposit Inconel 625

- Repair without the need for disassembly

Reviews

There are no reviews yet.