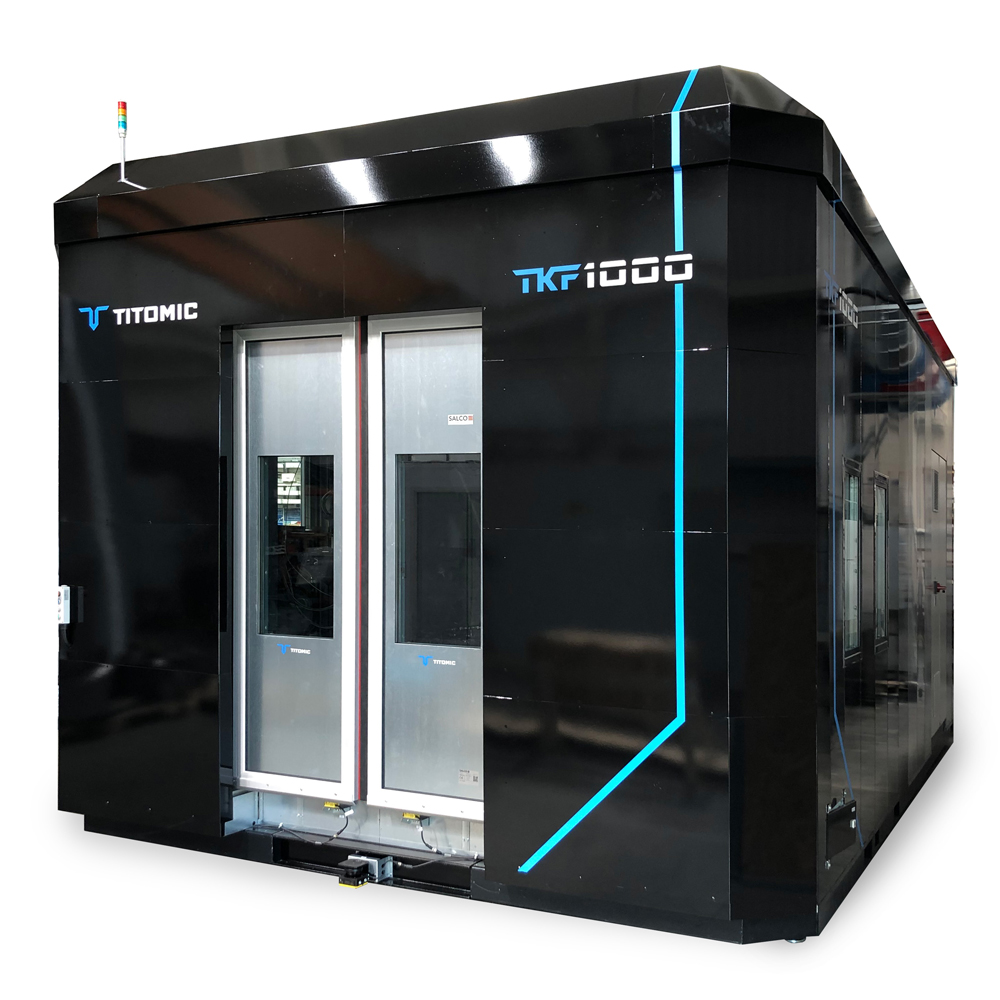

TITOMIC TKF 9000 Additive Manufacturing Systems

Fully automated custom additive manufacturing systems. Customised systems to solve your manufacturing challenges.

Bring a new age of automated manufacturing to your factory floor with the TITOMIC TKF 9000 additive manufacturing system. With an impressive 40.5 m3 build envelope, it unlocks the limitless possibilities of large-scale cold spray manufacturing with metals. So you can cut costs and reduce waste while producing parts faster, easier and more sustainably than ever before.

Features

- Automated robotic production

- Fuse dissimilar metals to create custom solutions

- Additive manufacturing without distortion or oxidation

- Create high-performance metal coatings

- Powder feeder accurate to 0.5μm without clogging

- Industry-leading build rates

- Cost-effective digital manufacturing

- Manufacturing with advanced materials

System

- Automated robotic production

- Kuka robot for 6-axis manoeuvrability

- Servo-controlled shuttle

- Intuitive touch panel interface

- Protective sound-dampening booth

- Dust extraction system for a safe and clean environment

Extraction system

- Based on 1000m3/hr to 1250m3/hr at the nozzle

- High vacuum on the tool principles for dust collection from the printing face

- Active on 6 6-axis robot head during deposition, otherwise may be used for general cleaning.

Reviews

There are no reviews yet.