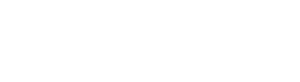

TITOMIC TKF 1000 – CUSTOM – a complete custom-built cold spray additive manufacturing solution, built to your specification – Faster, simpler, and on-demand.

With the TITOMIC TKF 1000 modular additive manufacturing system, you can put the power back in your hands, cut costs, and simplify your supply chain.

From prototyping to R&D, small-run production and on-demand manufacturing, the in-house system brings the limitless possibilities of cold spray technology to your factory floor.

Features Include:

- Automated robotic production

- Fuse dissimilar metals to create custom solutions

- Additive manufacturing without distortion or oxidation

- Combine multiple materials in parts

- Multiple powder feeders allow rapid manufacturing with dissimilar metals

- Industry-leading build rates

- Cost-effective digital manufacturing

- Manufacturing with advanced materials

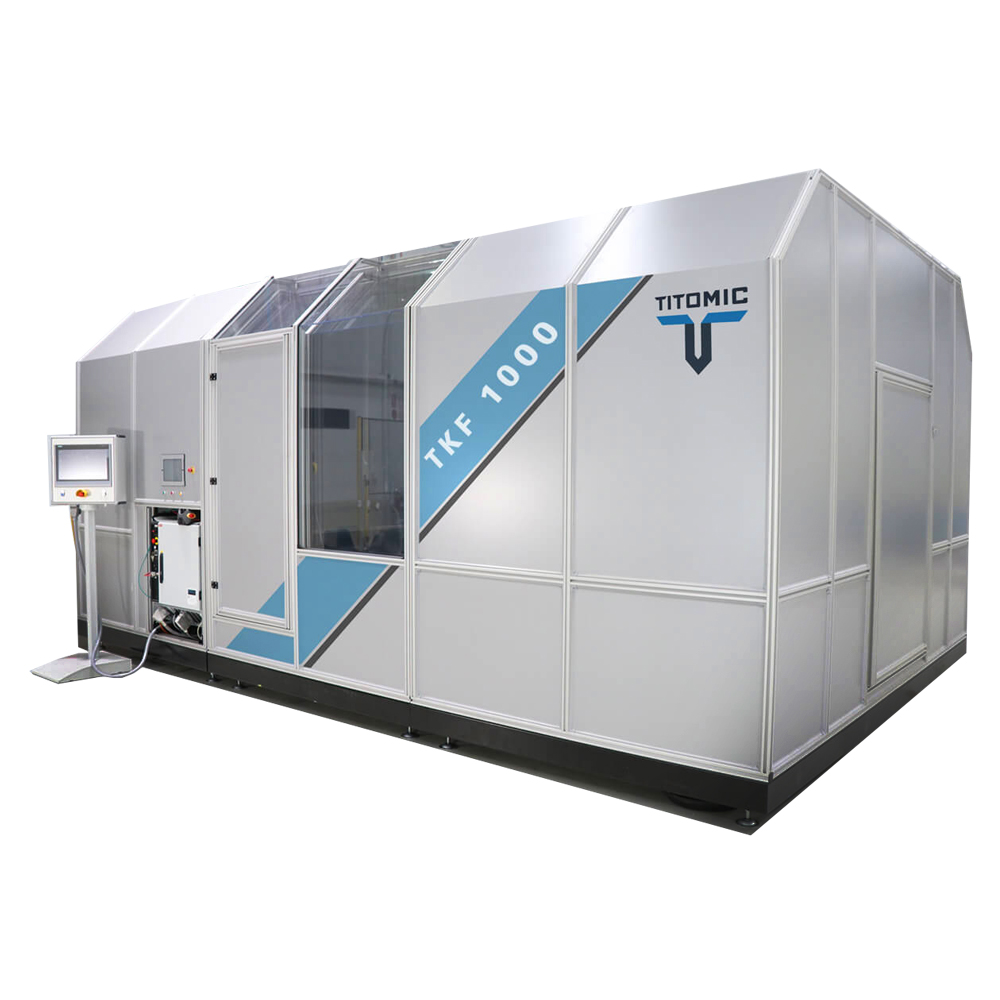

System features

- Large-scale metal additive manufacturing

Synchronised 6-Axis Robotics, Servo Positioning and TKF Controls

Intuitive touch panel interface

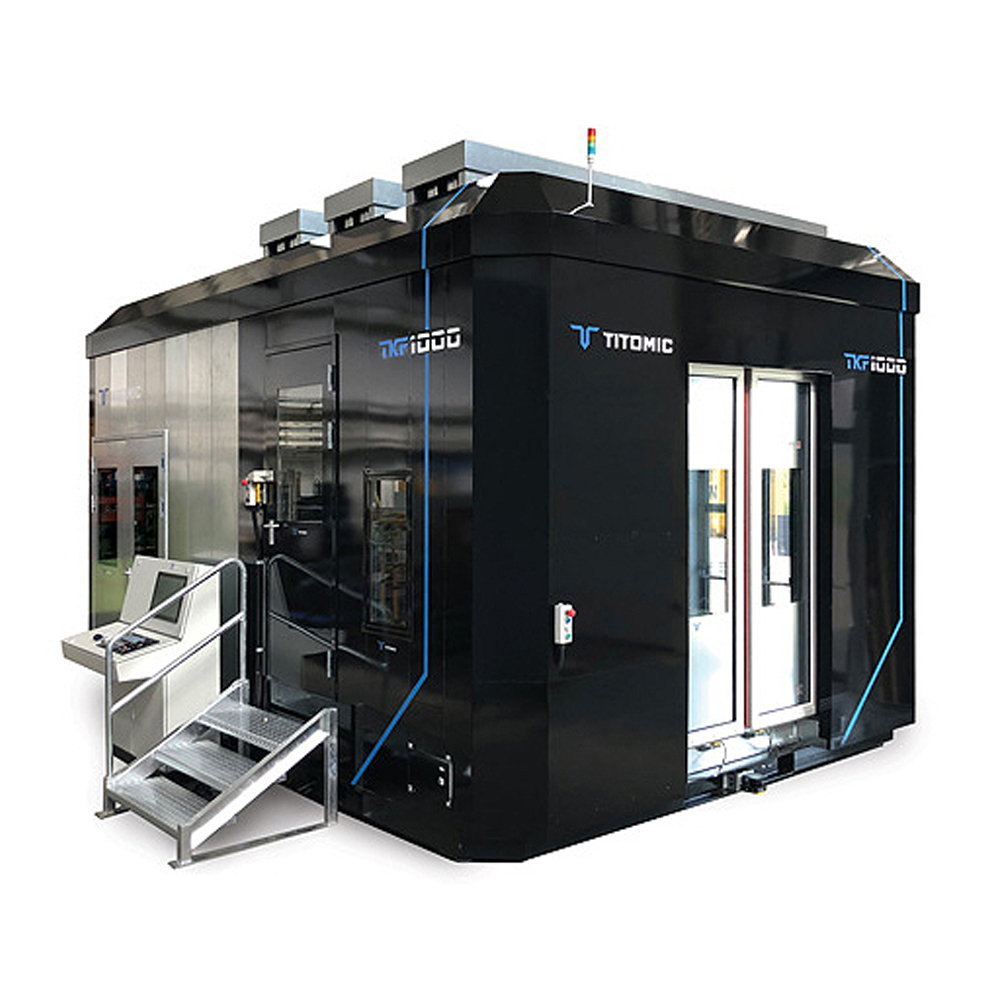

Protective sound-dampening booth

System enclosure

- Designed for easy operation and user experience

- Scratch-proof, polycarbonate viewing panels

- Easy access points for connecting services

- Fully insulated composite panel cell walls

- Automate the Bi-parting loading door with a sealing system

Downdraft extraction area

- Particles and operating gas are extracted via the floor

- Removable non-slip grating panels

- Simple connection to the existing dust collector with signal interfacing

- Ducted powder feed area for reloading and continuous operation

Vacuum System

- Plug and play integrated housekeeping vacuum

- Hi-vacuum to a single collection point

- 5m max anti-static vacuum hose

- 250m3/hr at 15 kPa

Component positioning shuttle

- Counter levered linear bearing mounts

- Component T-slot mounting table

- Precise servo-driven positioning

- Integrated component weight measuring and logging

- Removable stainless steel covers

- Cable chain for carrying component cables

Rotary component positioning unit

- Coordinated movement, speed control and positioning

- 500mm table diameter

- Max. speed 180RPM

Reviews

There are no reviews yet.