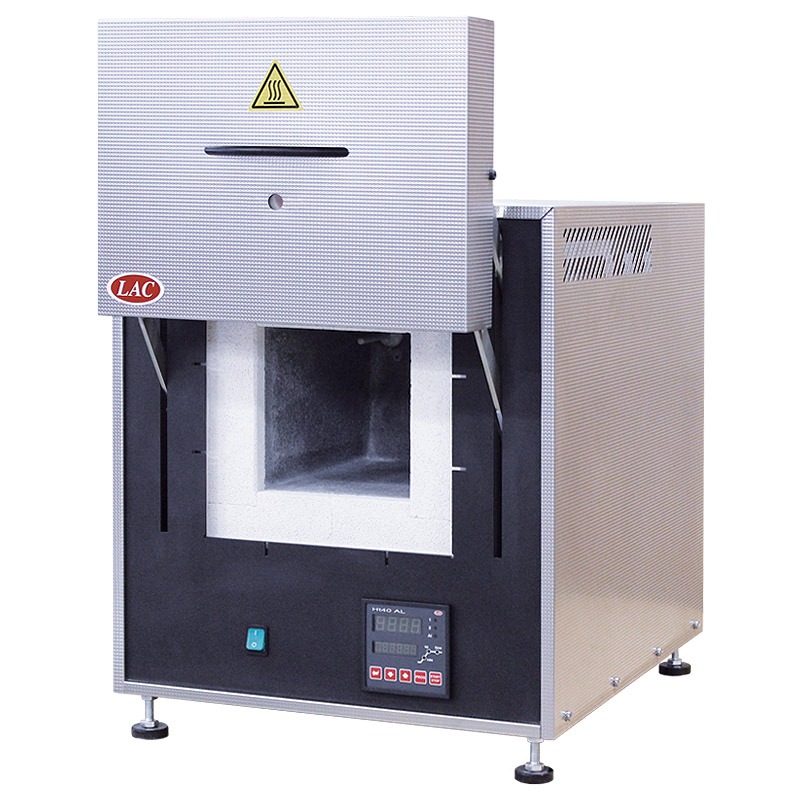

LMH muffle laboratory furnace up to 1200 °C

Specially designed for testing aggressive charges

The heating spirals are outside the furnace chamber and are covered with a resilient ceramic muffle, so aggressive flue gases cannot even reach them. The furnace is furthermore also protected with exhaust ventilation that prevents condensation of vapours during firing.

Benefits

- Easy to install, easy to control

- Custom adjustments

- Delivery times within just 2 days

- Noise-free operation

- 36-month warranty

- Immediate technical support

- Quick run-up to Tmax

- Even temperature distribution

- Mechanical durability

- Chemical durability

Charge treatment technology

(PS = partially suitable)

- Incineration, combustion, annealing loss (PS)

- Enamel firing (PS)

- Sintering

- Heat treatment of metal materials (PS)

- Melting metal materials

- Glass fusing

- Material testing

Technical parameters

| Furnace type | T max °C | Recommended operating temperature range in °C | Volume in l | External dimensions (w × h × d) mm | Internal dimensions (w × h × d) mm | Input in kW | Weight in kg | Protection* | Voltage V | Max. load capacity of bottom in kg |

| LMH 04/12 | 1200 | 700 - 1150 | 4 | 490×540×720 | 170×90×275 | 3,0 | 42 | 16/1 | 230 | 10 |

| LMH 07/12 | 1200 | 700 - 1150 | 7 | 490×540×720 | 170×170×275 | 3,0 | 48 | 16/1 | 230 | 10 |

| LMH 11/12 | 1200 | 700 - 1150 | 11 | 570×540×720 | 255×165×255 | 3,5 | 53 | 16/1 | 230 | 15 |

Standard equipment

- Ht40AL controller (1 programme: 2x run-up, 2x dwell)

- heating spiral coiled on muffle, outside the furnace space

- muffle insulated with mineral-fibre mat covered with insulation plates

- ventilation chimney for venting the furnace’s operational space

- protective glass in door slit

- “S” type thermocouple

- contactless switching relay for noise-free operation

- limit switch for safe opening of the door

- door manually opened upwards

- power cable fitted with one-phase plug

- tabletop variant

Optional accessories available at additional cost

- HtIndustry/Ht205 controller (30 programmes with 15 steps each)/Ht200 controller (30 programmes with 25 steps each, USB interface)

- injector with exhaust fan and pull interruptor (only with HtIndustry/Ht205/Ht200 controller)

- intake of protective atmosphere (manually or automatically controlled gas intake)

- calibration of the controller’s measuring input

- RS232 or EIA485 interfaces including software and cabling

- HtMonit set (software + interface)

Note: When combining accessories (at additional cost), consult with our technical office.